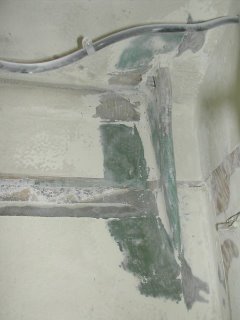

With the trusty Porter-Cable DA sander and a collection of 40 and 80 grit disks, I attacked the tough old paint around the aft chainplate knees. I don't know what Pearson used but it is tenaciously adhered and it doesn't appreciate being sanded off. In fact, the sanded paint gets even with its aggressor by creating masses of incredible dust which settle everywhere on the boat - this despite heroic ventilation attempts.

Progress was discouraging. The paint was tough and access to the chainplate knees was not good. Neither my DA or the orbital palm sander will reach the nooks and corners around the knees.

It was sometime that evening, after arriving home from the boat, that it occurred to me that the old paint I was grinding might be lead paint. I posted on the Plastic Classic forum to see if anyone else had run into the lead paint problem on their Triton. Eventually I called a local company (Channel Coast Corporation) which specializes in lead paint remediation and the like. They suggested I take samples to be sent in for lab testing, which I did - taking one chip sample from the hull paint in the head compartment, and another from the paint atop the port settee.

The first sample came back completely negative, and the second came back with .23% lead by weight - yes, 23 hundreths of a percent. Evidently the legal definition of lead paint around here is > .5% ... so, it's not lead paint, at least legally! The risk seems small at this point if I simple and prudent measures like P100 respirators and proper cleanup.