Thursday, January 17, 2008

Down to a bare mast...

Saturday, January 12, 2008

Wednesday, January 02, 2008

The WC Triton sliding hatch...

Formica goes in...

Final step with the bulkhead Formica was to roll on an even layer of waterproof DAP contact cement on the both the bulkhead and laminate surfaces, wait for it to dry, and then carefully set the laminate in place on top of cardboard sliders. Once in place, I removed the sliders one by one and then pressed the laminate onto the bulkhead. To make sure it was well adhered I used a slick 'pressure block'

Bulkhead Formica

I'm covering the main bulkhead with Formica as an experiment, since I expect it to need less maintenance than paint. I'm using Formica Neutral White in matte finish, which a local supplier had in a 5x8' sheet for about $80. I'm using a set of straight-cut laminate shears and a utility knife for most cutting.

The first step was to transfer the tick-stick pattern to the Formica. This is a simple if tedious matter of lining up the tick stick with each set of registrations and gradually building the pattern outline on the material.

Then comes the cutting, which is a damn delicate process with Formica, which loves to crack and flake if you put too much tearing stress on it. I finally got both sides cut out with only one throwaway piece, which I can use for other stuff anyway.

Later I took the cutouts down to the boat for final fitting, which I did with a utility knife. It's impossible to get a great fit but I managed to get fairly uniform a 1/8"gap in most places. Edges will be covered by trim anyway, so it's not critical to fit the laminate really tightly.

Later I took the cutouts down to the boat for final fitting, which I did with a utility knife. It's impossible to get a great fit but I managed to get fairly uniform a 1/8"gap in most places. Edges will be covered by trim anyway, so it's not critical to fit the laminate really tightly.

The first step was to transfer the tick-stick pattern to the Formica. This is a simple if tedious matter of lining up the tick stick with each set of registrations and gradually building the pattern outline on the material.

Then comes the cutting, which is a damn delicate process with Formica, which loves to crack and flake if you put too much tearing stress on it. I finally got both sides cut out with only one throwaway piece, which I can use for other stuff anyway.

What's been happening lately...

Lots of stuff happening lately, through the end of November and through December...

I removed the boom in anticipation of the rig refit planned for January. It fit well on top of car for the trip home to SB. I'll be removing all the hardware, straightening a mild bend, and repainting the boom.

I also made some progress on the new compression posts for thee main bulkhead. Every Triton I've ever seen in person or in photos has had these posts running vertically across the main bulkhead, but Nevermind lacks them. They are mostly for adding buckling resistance to the main bulkhead despite being called compression posts. I'm hoping they'll also look good. I'm making each beam out of three laminated layers of 1/2" exterior Baltic birch ply. This ply has a nice clear face veneer and thin plies of alternating light and dark wood, which should look great when varnished. I built a special jig for the circular saw to rip the 5' by 2" lengths of ply (12 in all).

Some of the basic strips after cutting.

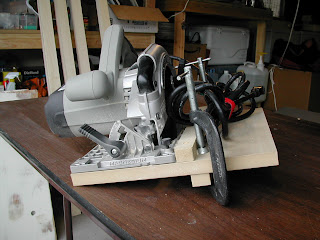

A closer look at the MDF jig I made for long rip cuts in ply. It's like a minature and upside-down table saw. The clamps hold down the adjustable 'fence'. The one problem with jigs like this is that they are very prone to kickback because the fence runs along the edge outside of the cut and the cut gets compressed against the blade. I used light pressure and great care at the end of the cut and had no drama. Note that this circular saw is one of the left-blade Porter Cables, so everything is a mirror image of the normal blade-right sidewinders.

I removed the boom in anticipation of the rig refit planned for January. It fit well on top of car for the trip home to SB. I'll be removing all the hardware, straightening a mild bend, and repainting the boom.

I also made some progress on the new compression posts for thee main bulkhead. Every Triton I've ever seen in person or in photos has had these posts running vertically across the main bulkhead, but Nevermind lacks them. They are mostly for adding buckling resistance to the main bulkhead despite being called compression posts. I'm hoping they'll also look good. I'm making each beam out of three laminated layers of 1/2" exterior Baltic birch ply. This ply has a nice clear face veneer and thin plies of alternating light and dark wood, which should look great when varnished. I built a special jig for the circular saw to rip the 5' by 2" lengths of ply (12 in all).

Some of the basic strips after cutting.

A closer look at the MDF jig I made for long rip cuts in ply. It's like a minature and upside-down table saw. The clamps hold down the adjustable 'fence'. The one problem with jigs like this is that they are very prone to kickback because the fence runs along the edge outside of the cut and the cut gets compressed against the blade. I used light pressure and great care at the end of the cut and had no drama. Note that this circular saw is one of the left-blade Porter Cables, so everything is a mirror image of the normal blade-right sidewinders.

Monday, November 19, 2007

Main chainplates are IN!

It felt great to bolt in those new chainplates. There are only a few small details left to wrap up, like installing chainplate covers, painting the primed areas around the uppers, and opening an area for a nut on the back of the #4 bolts on the uppers (there are 5 3/8" SS bolts for each chainplate).

I was also able to put the final coats of paint on the head areas and the port settee (shown). For the settee I'm using Benjamin Moore Super Spec semi-gloss alkyd enamel, color-matched to my new formica. It's really good paint, as it levels nicely and covers very well.

Monday, November 12, 2007

Fires from CIH

Saturday, November 10, 2007

Painting the head, and wrapping up the chainplates

First thing today was to test-fit the new covers, which fit great and looked super! I'm going to take the winch covers back to stitch an elastic grip around the inside perimeter so they don't fly off the winches in heavy wind.

I faired around the upper chainplate slots. Fairing and painting are all that's left before I can bolt in those chainplates for good and call this epic project DONE. Replacing chainplates is a big job - well, it was this time, because in every case I wanted to upgrade the marginal original installation with something beefier and easier to service.

After some final fairing, and sanding in the head, I gave everything an acetone wipe-down and then rolled on a coat of white Bilge-Kote. You can't imagine how great it feels to finally hide all that ugly bare fiberglass, plywood, old paint and general filth. Now I can see how the new head/hanging locker will look. The bare portions of the bulkheads are where I'll place white satin Formica - the paint will mostly be hidden by cabinetry but the Formica will be exposed.

Friday, November 09, 2007

Canvas work - winch covers, grill cover

Subscribe to:

Posts (Atom)