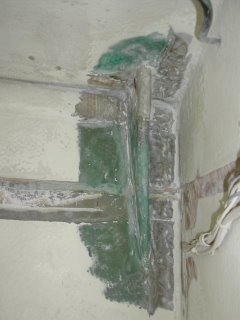

The fiberglass work on the chainplate knees continued this weekend as I added a layer of 24 oz. roving over last week's layer of 10 oz. cloth. Now the knees are becoming smoother and looking better! There are certainly far more substantial than before. One more layer of 10 oz. and I'll be done. I would have laid up the final layer, but ran out of resin...

The fiberglass work on the chainplate knees continued this weekend as I added a layer of 24 oz. roving over last week's layer of 10 oz. cloth. Now the knees are becoming smoother and looking better! There are certainly far more substantial than before. One more layer of 10 oz. and I'll be done. I would have laid up the final layer, but ran out of resin...

In other work, I

- Replaced the old Group 24 500CCA starting battery with a new Group 26 450 CCA.

- Replaced both engine belts - Gates 3VX350 for the alternator/freshwater/crankshaft belt, and a Westerbeke belt for the raw water pump. A 3vx-220 should fit the raw water pump, but the 3vx-250 is too long, and it's the smallest McMaster carries. There is a local Gates dealer...I'll have to drop by.

- Reinstalled the rebuilt raw water pump.

- Repaired the broken terminal clamp on the negative cable for the starting battery.

- Attempted to fit a length of fabric-reinforced Shields 1.5" ID host on the port cockpit drain & seacock. Right now I have some fairly cheesy corrugated hose on there which works fine but doesn't inspire great confidence. The big fabric-reinforced hose wasn't flexible to go on well...even when I forced the fit, it still leaked.

- Took the boat out for a 45 minute steam around the harbor...it's been a while.